Fields of Application

Pasta

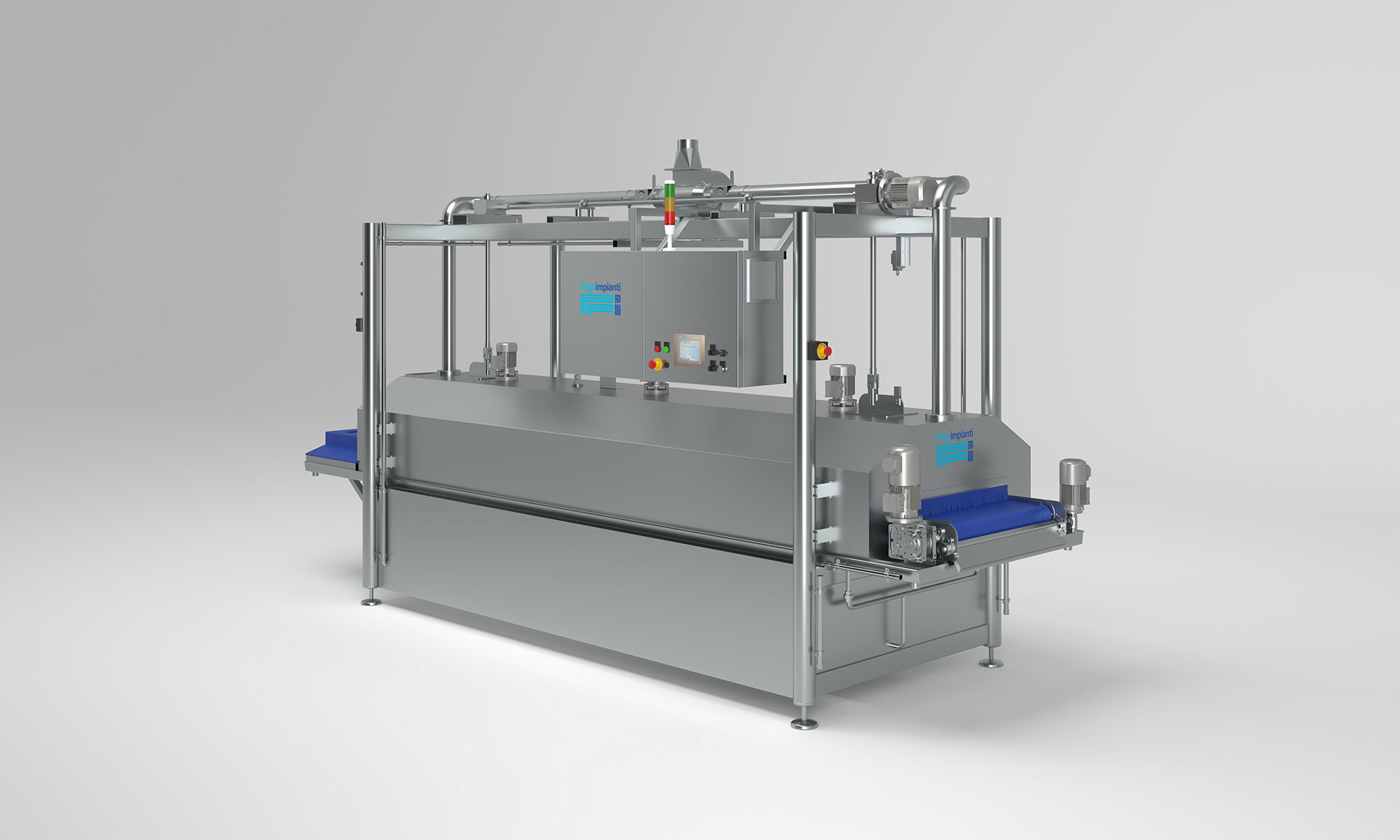

STRAIGHT PASTEURISER

Frigo Impianti’s ‘P.V.R.’ straight pasteuriser represents the top of the range for the treatment of fresh filled and non-filled pasta.

As opposed to common pasteurisers on the market that use saturated steam to pasteurise and do not feature ventilation, P.V.R. is equipped with a special technology that uses a “mixture of heat and ventilated steam” as a source of pasteurisation.

The machine is composed of a forced ventilation system for perfect product treatment and two vapour heating coils and a mutually independent humidification circuit, that allows temperature and humidity control inside the pasteurisation chamber.

Ventilation speed, temperature and humidity are electronically adjustable from a digital control panel.

The end result of P.V.R. use will be to obtain a quality product with a drier surface and a more “natural” (not shiny) appearance, like before pasteurisation.

The advantages of the Frigo Impianti P.V.R. Tunnel are:

- Absolute adaptability to any production line and space for installation;

- Easily washable and inspectable structure;

- Structure made entirely of AISI 304 stainless steel;

- Belt designed to eliminate unwanted marking on processed products;

- Easy to transport and install.