Our Technology

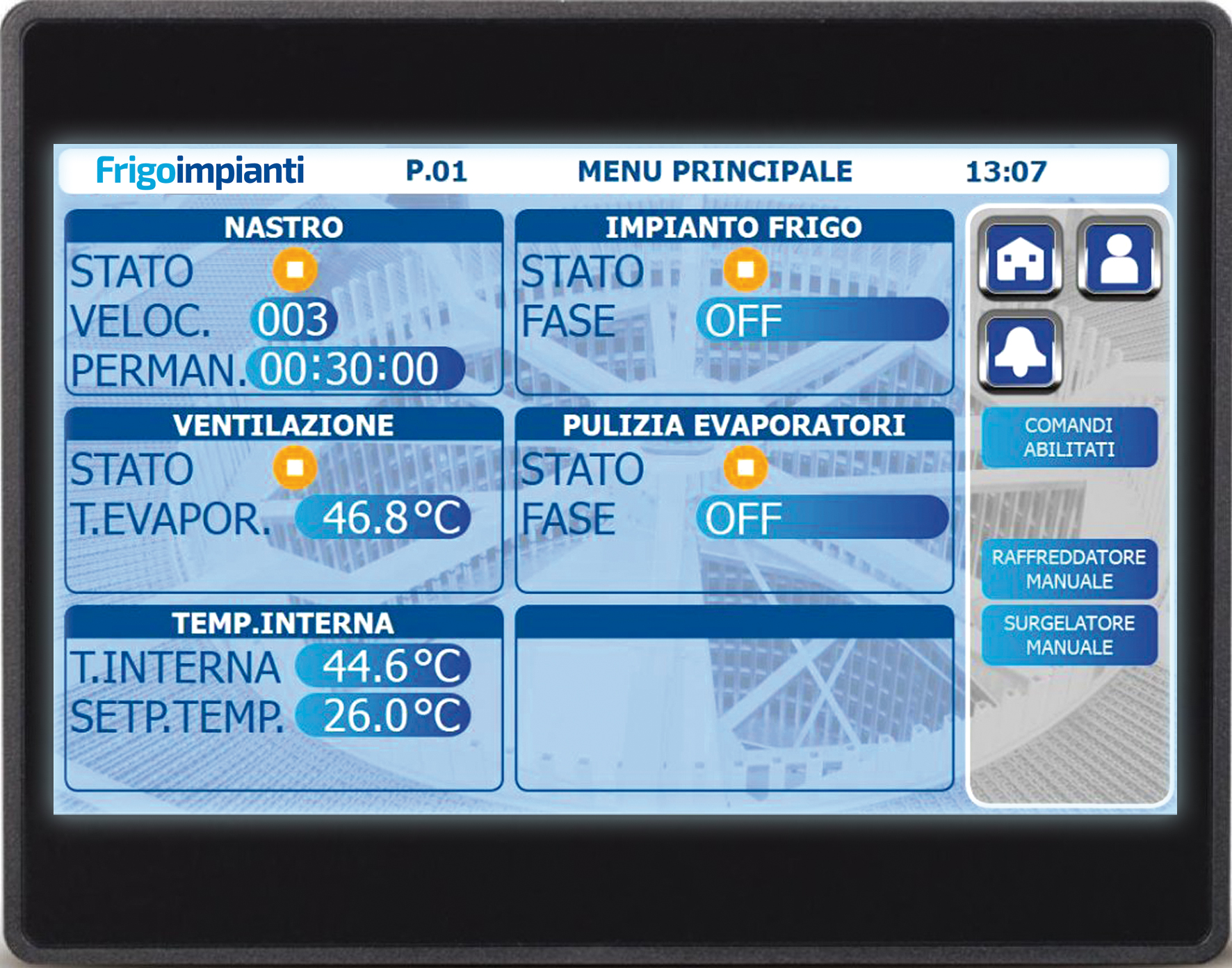

HMI TUNNEL:

The human machine interface (HMI) consists of 65,000-colour touch-screen panels in 16:9 format and TFT technology.

The multi-machine software, developed by Frigo Impianti’s IT department, is configured to manage the various machine types and in particular:

- Display the status of the system’s operating parameters (plc inputs/outputs, room temperature reading, status of inverters driving the motors, etc.)

- Set software control parameters (belt speed, room temperature setpoint, ventilation speed, etc.)

- Switch the various system functions on/off

- Display and reset any alarms

The panel can also be connected, via Ethernet, to the customer’s company network in order to display, via VNC protocol, the status of the system, as if one were in front of the panel itself.

PLC TUNNEL:

System operation is provided by a PC, equipped with a number of additional input-output cards and a communication port that, via an Ethernet switch, allows data to be exchanged with the HMI, inverters and the remote assistance system.

The multi-machine software, developed by Frigo Impianti’s IT department, is configured to manage the various machine types and in particular:

- Read the status of temperature sensors

- Based on the operator’s settings via the hmi, control the various utilities (belt, refrigeration system, ventilation, evaporator cleaning, etc.)

- Switch the various system functions on/off

- Modify machine behaviour based on process timers or reading sensor drifts

- Receive various alarms from the system and, consequently, interrupt the operation of the relevant utilities